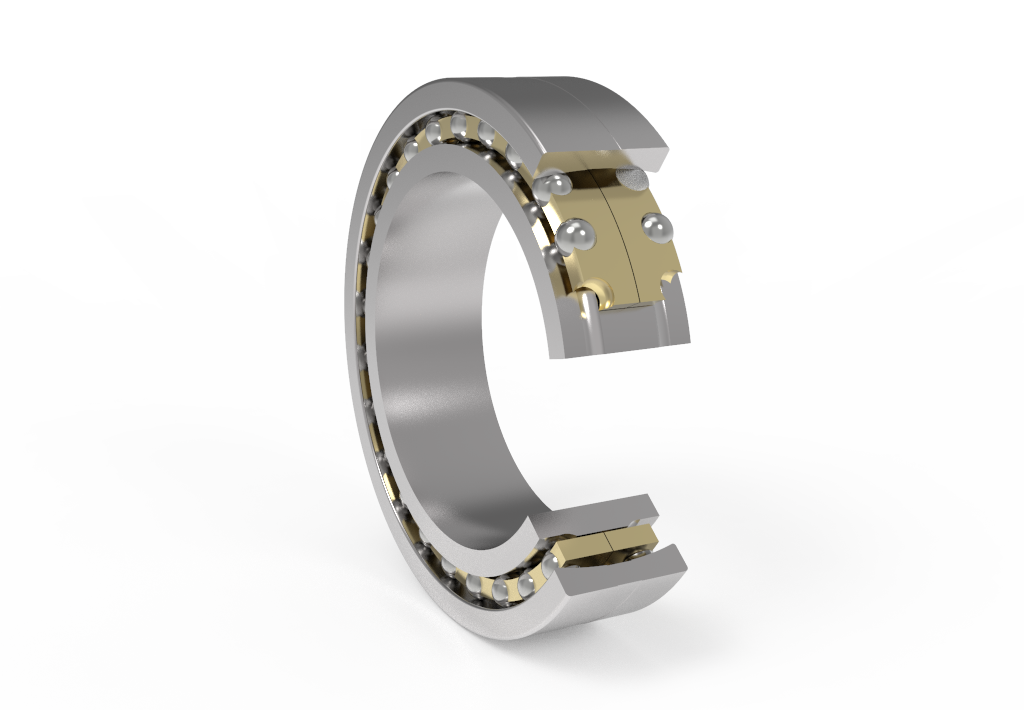

SBB have two rows of balls, the outer ring has a common concave spherical raceway, and the center of curvature is the same as the center of the bearing. Even if the inner ring, the steel ball and the cage are slightly inclined relative to the outer ring, they can rotate. Therefore, the bearing is self-aligning and will not be affected by the misalignment of the shaft relative to the bearing housing. It is mainly used to bear radial load, but can also bear a small amount of axial load, and generally cannot bear pure axial load. It is especially suitable for bearing applications where considerable shaft deflection or misalignment may occur. For example, precision instruments, low-noise motors, transmission shafts of automobiles, motorcycles, woodworking machinery, textile machinery, mining machinery, electromechanical equipments, plastic machinery, office equipments, medical equipments, fitness and sports equipments, and general machinery, etc. are the most widely used type of bearings in the machinery industry.

| Basic dimensions mm | Basic load ratings kN | Limit Rotational Speed rmin | Bearing part number | Mounting dimensions mm | Axial load factor | Mass kg | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| d | D | B | rmin | Cr | Cor | Grease lubrication | Oil lubrication | Cylindrical hole Bearing part number | Conical hole Bearing part number | damin | damax | ramax | e | Y1 | Y2 | Y0 | Mass |

| 25 | 52 | 15 | 1 | 12.1 | 3.30 | 11000 | 14000 | 1205TN1 | 31 | 46 | 1 | 0.27 | 2.3 | 3.6 | 2.4 | 0.137 | |

| 25 | 62 | 17 | 1.1 | 17.9 | 5.00 | 9600 | 13000 | 1305TN1 | 32 | 55 | 1.1 | 0.28 | 2.3 | 3.5 | 2.4 | 0.249 | |

| 30 | 62 | 16 | 1 | 15.7 | 4.70 | 9200 | 12000 | 1206 | 36 | 56 | 1 | 0.25 | 2.5 | 3.87 | 2.62 | 0.228 | |

| 30 | 62 | 20 | 1 | 15.2 | 4.60 | 9100 | 12000 | 2206 | 36 | 56 | 1 | 0.39 | 1.63 | 2.53 | 1.71 | 0.260 | |

| 30 | 62 | 20 | 1 | 15.4 | 4.60 | 8900 | 12000 | 2206TN1 | 36 | 56 | 1 | 0.39 | 1.63 | 2.53 | 1.71 | 0.242 | |

| 30 | 72 | 27 | 1.1 | 31.4 | 8.70 | 8400 | 11000 | 2306 | 37 | 65 | 1.1 | 0.44 | 1.43 | 2.22 | 1.5 | 0.515 | |

| 30 | 72 | 27 | 1.1 | 31.4 | 8.70 | 8400 | 11000 | 2306TN1 | 37 | 65 | 1.1 | 0.44 | 1.43 | 2.22 | 1.5 | 0.494 | |

| 35 | 72 | 17 | 1.1 | 15.8 | 5.10 | 8000 | 10000 | 1207 | 42 | 65 | 1.1 | 0.23 | 2.74 | 4.24 | 2.87 | 0.318 | |

| 35 | 72 | 17 | 1.1 | 15.1 | 4.80 | 8000 | 10000 | 1207TN1 | 42 | 65 | 1.1 | 0.23 | 2.74 | 4.24 | 2.87 | 0.309 | |

| 35 | 72 | 23 | 1.1 | 21.7 | 6.70 | 8000 | 10000 | 2207 | 42 | 65 | 1.1 | 0.37 | 1.69 | 2.61 | 1.77 | 0.604 | |

| 35 | 72 | 23 | 1.1 | 21.7 | 6.70 | 8000 | 10000 | 2207TN1 | 42 | 65 | 1.1 | 0.37 | 1.69 | 2.61 | 1.77 | 0.587 | |

| 35 | 80 | 21 | 1.5 | 25.1 | 7.90 | 7100 | 9000 | 1307 | 44 | 71 | 1.5 | 0.25 | 2.56 | 3.97 | 2.69 | 0.507 | |

| 35 | 80 | 21 | 1.5 | 23.9 | 7.40 | 7100 | 9000 | 1307TN1 | 44 | 71 | 1.5 | 0.25 | 2.56 | 3.97 | 2.69 | 0.486 | |

| 35 | 80 | 31 | 1.5 | 39.4 | 11.1 | 7500 | 9400 | 2307 | 44 | 71 | 1.5 | 0.46 | 1.36 | 2.11 | 1.43 | 0.675 | |

| 35 | 80 | 31 | 1.5 | 39.4 | 11.1 | 7500 | 9400 | 2307TN1 | 44 | 71 | 1.5 | 0.46 | 1.36 | 2.11 | 1.43 | 0.659 | |

| 40 | 80 | 18 | 1.1 | 19.2 | 6.50 | 7000 | 8800 | 1208 | 47 | 73 | 1.1 | 0.22 | 2.87 | 4.45 | 3.01 | 0.410 | |

| 40 | 80 | 18 | 1.1 | 18.5 | 6.10 | 7000 | 8800 | 1208TN1 | 47 | 73 | 1.1 | 0.22 | 2.87 | 4.45 | 3.01 | 0.402 | |

| 40 | 80 | 23 | 1.1 | 22.3 | 7.40 | 7000 | 8900 | 2208 | 47 | 73 | 1.1 | 0.33 | 1.9 | 2.94 | 1.99 | 0.520 | |

| 40 | 80 | 23 | 1.1 | 21.3 | 6.90 | 7000 | 8900 | 2208TN1 | 47 | 73 | 1.1 | 0.33 | 1.9 | 2.94 | 1.99 | 0.476 | |

| 40 | 90 | 23 | 1.5 | 29.5 | 9.80 | 6400 | 8100 | 1308 | 49 | 81 | 1.5 | 0.24 | 2.62 | 4.05 | 2.74 | 0.714 | |

| 40 | 90 | 23 | 1.5 | 28.2 | 9.10 | 6400 | 8100 | 1308TN1 | 49 | 81 | 1.5 | 0.24 | 2.62 | 4.05 | 2.74 | 0.688 | |

| 40 | 90 | 33 | 1.5 | 44.8 | 13.4 | 6600 | 8300 | 2308 | 49 | 81 | 1.5 | 0.43 | 1.45 | 2.25 | 1.52 | 0.959 | |

| 40 | 90 | 33 | 1.5 | 42.3 | 12.3 | 6600 | 8300 | 2308TN1 | 49 | 81 | 1.5 | 0.43 | 1.45 | 2.25 | 1.52 | 0.901 | |

| 45 | 85 | 19 | 1.1 | 21.9 | 7.40 | 6500 | 8300 | 1209 | 52 | 78 | 1.1 | 0.21 | 2.94 | 4.55 | 3.08 | 0.469 | |

| 45 | 85 | 19 | 1.1 | 21.9 | 7.40 | 6500 | 8300 | 1209TN1 | 52 | 78 | 1.1 | 0.21 | 2.94 | 4.55 | 3.08 | 0.458 | |

| 45 | 85 | 23 | 1.1 | 23.3 | 8.20 | 6500 | 8200 | 2209 | 52 | 78 | 1.1 | 0.31 | 2.04 | 3.15 | 2.13 | 0.553 | |

| 45 | 85 | 23 | 1.1 | 21.5 | 7.30 | 6500 | 8200 | 2209TN1 | 52 | 78 | 1.1 | 0.31 | 2.04 | 3.15 | 2.13 | 0.500 | |

| 45 | 100 | 25 | 1.5 | 38.0 | 12.9 | 5800 | 7300 | 1309 | 54 | 91 | 1.5 | 0.25 | 2.53 | 3.92 | 2.66 | 0.951 | |

| 45 | 100 | 25 | 1.5 | 36.3 | 12.0 | 5800 | 7300 | 1309TN1 | 54 | 91 | 1.5 | 0.25 | 2.53 | 3.92 | 2.66 | 0.920 | |

| 45 | 100 | 36 | 1.5 | 54.1 | 16.5 | 5900 | 7400 | 2309 | 54 | 91 | 1.5 | 0.42 | 1.51 | 2.33 | 1.58 | 1.24 | |